OUR SERVICES

Engineering Excellence Since 1965

CONDITION MONITORING

Motor Circuit Analysis

Winding problems can be detected before your electric motor or pump fails!

It is a technology that lets you examine the electrical health of a motor through measuring multiple electrical properties of the windings. The MCA unit performs five measurements on each of the three winding phases. These tests will establish phase to phase, turn to turn and coil to coil faults along with insulation to ground problems

iTIG Tester

iTIG Analyzer

Tests include Hipot, Mega ohm, PI and Surge Comparison. These tests will establish phase to phase, turn to turn and coil to coil faults along with insulation to ground problems

Electrical Signature Analysis

All Test Pro Line

Electrical Signature Analysis (ESA) is the term used for the evaluation of the voltage and current waveforms. This provides an increased advantage to diagnose power related, motor related and load related problems. It also provides several unique abilities when related to power quality, DC motor analysis, generator analysis as well as other advantages, ESA is a system used for analyzing or trending dynamic, energized systems

Thermography

What makes Thermography so useful?

It is non-contact and non destructive testing: In other words thermography does not intrude upon or affect the target at all

It is two-dimensional: Meaning comparison between areas of the target is possible

It is real time: That allows us to do very fast scanning of stationary targets

Thermography is the use of an infrared imaging and measurement camera to "see" and "measure" thermal energy emitted from an object. Thermal, or infrared energy, is light that is not visible because its wavelength is too long to be detected by the human eye; it's the part of the electromagnetic spectrum that we perceive as heat

Vibration Analysis

Vibration Analysis benefits both the operator and the maintenance technician

Enables the identification of the machine faults

Provides information on root causes

Localizes the affected components

Allows early planning of maintenance measures

Vibration analysis consists in listening inside the machine, Each component vibrates differently and generates a characteristic noise that leaves a typical fingerprint in the spectrum in the form of a linear pattern. If damage is present, the pattern stands out from the noise floor. This allows the specialist to recognize, for example, whether the problem comes from unbalance, misalignment or bearing damage. In addition to an accurate diagnosis it is generally also possible to determine whether urgent action is necessary or whether it can wait until the next scheduled servicing.

Stroboscope

Monarch Nova Scope

The Stroboscope is a portable, compact, instrument that enable the motion of rotating or reciprocating machinery to appear frozen. They allow such applications as fan blades, couplings, gear wheels, machine tool spindles and belt drives to be inspected while running

ELECTRICAL SERVICES

Electric Motor &

Armature Rewinding

Ensure an efficient quality rewind

How to define a quality rewind repair? Perform a core loss test on the stator core to establish if the complete core is in good condition. Perform a thermal scan on the core to establish any hot spots that may have occurred during winding failure. Perform a rotor bar test on the rotor to establish if the rotor is in good condition.

Pump

Installations

For all your pump installation needs

Please contact our sales team for any new installations and enquiries.

MECHANICAL SERVICES

On-site and

In-house Balancing

Balancing In-house and on-site on fans, In-house balancing on mulchers.

Balancing, whether done on-site or in-house, is key to preventing the damaging effects of imbalance on rotating equipment. On-site balancing involves adjusting components directly at the installation site, while in-house balancing typically takes place in a controlled workshop environment. Both methods help reduce vibrations, improve machinery performance, and extend the lifespan of components. Balancing ensures smooth operation, preventing issues such as bearing wear, energy inefficiency, and excessive maintenance costs.

Laser

Alignment

extends the life span of motors, bearings and attached components.

Laser alignment is a precision technique used to ensure that machine components, such as shafts, are properly aligned. Using a laser beam, the system detects even the slightest misalignment between parts, which can cause unnecessary wear, energy loss, and vibrations. The system provides real-time data, allowing for immediate adjustments to achieve optimal alignment. This process helps improve equipment life, efficiency, and reduces the likelihood of breakdowns, making it a critical step in preventative maintenance.

Lathe Machining

Machining-Lathe capacity Ø1.4M x 4M length, c - c

Our cutting-edge facility offers specialized metal spray services to restore components, precisely grinds seal and bearing surfaces, and meticulously refurbishes mechanical parts. We excel in manufacturing new, bespoke shafts with precision. Our advanced methods guarantee every component meets top quality and performance standards.

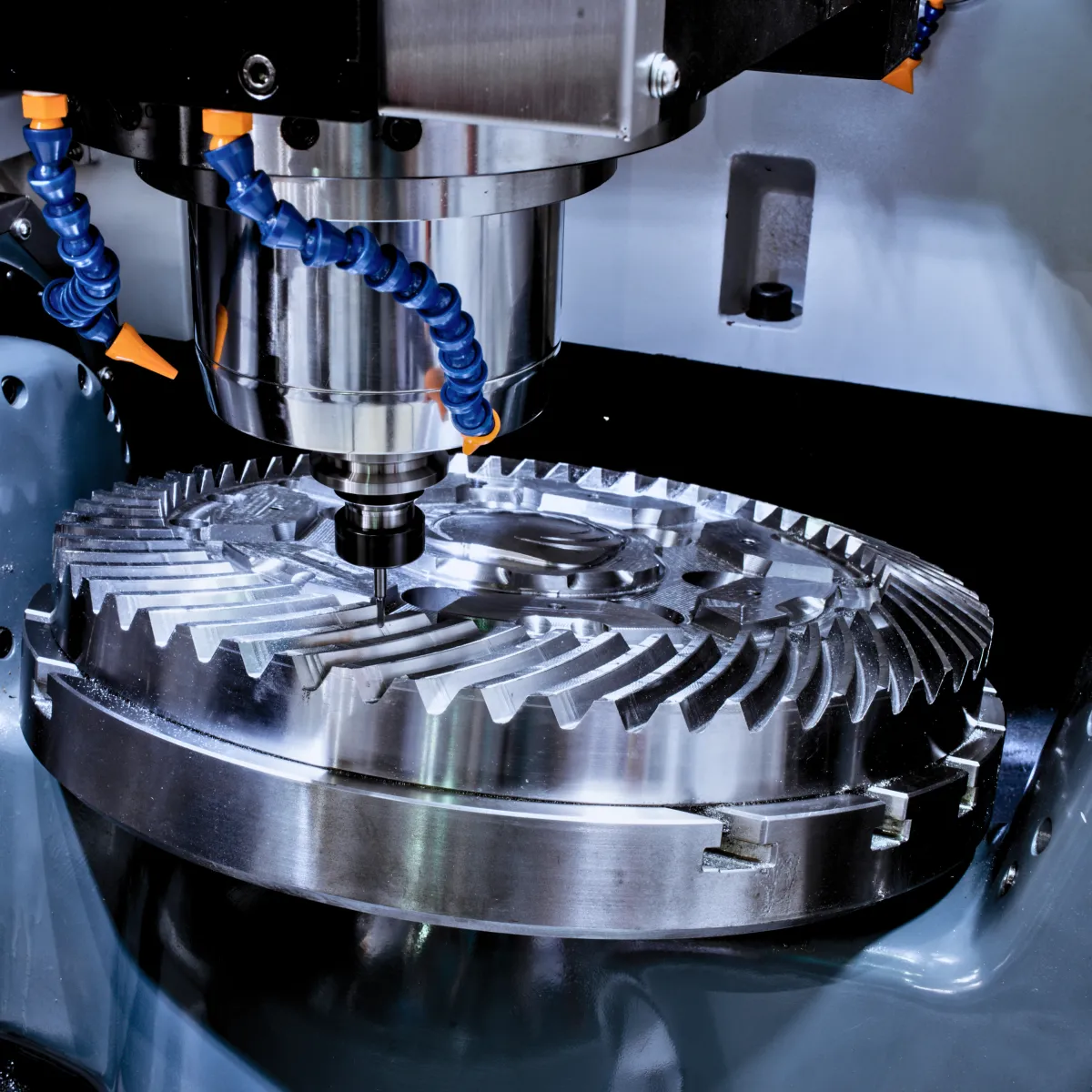

CNC Machining

Manufacturing of various components & parts.

The term CNC stands for 'computer numerical control', and the CNC machining definition is that it is a subtractive manufacturing process which typically employs computerized controls and machine tools to remove layers of material from a stock piece—known as the blank or workpiece—and produces a custom-designed part.

Belzona Protective Coating

Factory Maintenance